In hot weather all that weight concentrated at the bottom of a metal jack stand or floor jack can punch divots into asphalt warmed by the sun or high summer temperatures so choose concrete.

Using jack stands on gravel.

Same for your floor jack use it on a long board or thick piece of plywood doubled up thickness.

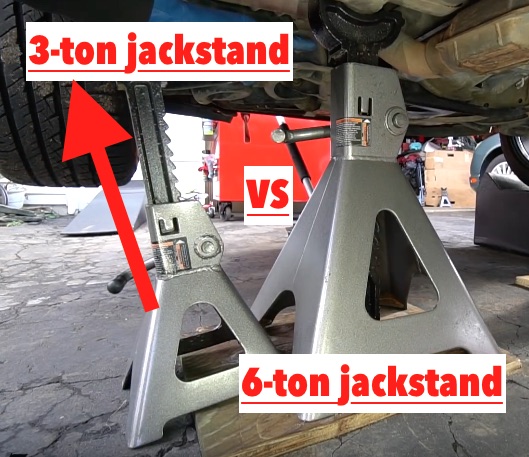

Get some decent jack stands.

The 8 direction running side to side to set the jack stands on.

Mattm we all wish we could have tv quality fully equipped garages with fancy lifts and all of the tools a guy could dream of but in reality many of us me included are still working on our backs under a car in the driveway once in a while.

How to safely setup jack stands on blacktop stone dirt posted.

But i d cut 3 4 pieces that are 6 larger on each side then the base of your jack stands.

I guess i assume you are using jack stands.

If you must use jackstands on gravel use a single 2x12 to spread the load out between the two jackstands.

Gives you something to roll the floor jack on.

This does five things.

If you have to work on gravel the plywood idea is a good one.

Don t support a car only with a jack.

If lifting just one wheel lifting just that corner of the vehicle is a good idea.

So put it in first gear or park and set the parking brake.

Question about using a jack and jackstands on gravel by anonymous not verified 12 apr 2014 i am basically forced to do it on gravel as the only level ground that is concrete is the parking lot down at the lake nearby and i d rather not have to go down there to do work on my truck.

To use jack stands start by activating your vehicle s parking brake and jacking up the vehicle with a hydraulic floor jack so the tires are 2 3 inches off the ground.

Jack up the vehicle using a solid jacking point leaving enough room for the jack stand to support the car.

October 6 2015 by.

If lifting the entire front or rear choose a jack point in the center of the front or rear suspension or frame.

Working on gravel or grass can allow the jack stand to shift off the vertical and tip.

I use a full sheet of 3 4 a b or a c plywood sideways to the car ie.

Make the board longer than the car is wide to allow the load to be spread out and chock the rear wheels tightly.