Scanning it is found that damage initiates by fibre microbuckling a fibre instability failure mode which then is followed by yielding of the matrix to form a fibre kink band zone that leads to final fracture.

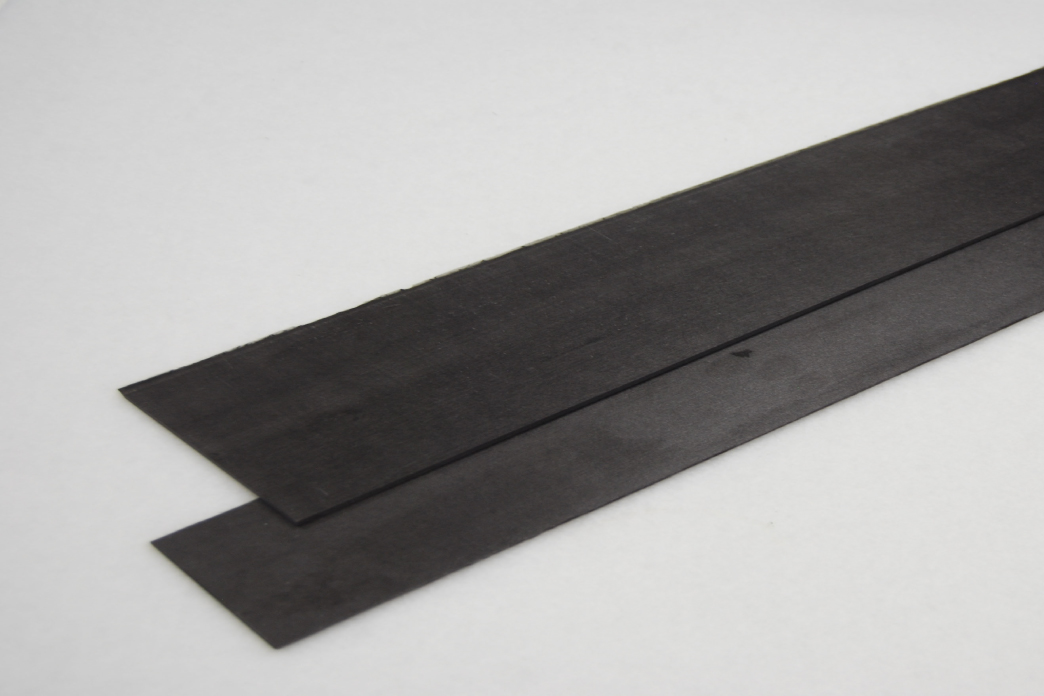

Unidirectional composite laminate.

The in plane shear and compressive properties of unidirectional ud hts40 977 2 carbon fibre toughened resin cf tr laminates are investigated.

Basics of composite laminates using lamination parameters elastic constants for a unidirectional lamina.

Unidirectional and short fiber composite behavior.

A small amount of fibre or other material may run in other directions with the main intention being to hold the primary fibres in position although the other fibres may also offer some structural properties.

This discussion will reinforce the conclusion that a 90 0 ns laminate is the logical choice for use in backing out unidirectional composite strengths.

Note that specimen width is not a factor because both gripping area and applied force vary in direct proportion to specimen width.

The curved laminate failed unstably by delaminations developing around the curved region of the laminate at different depths through the thickness until virtually all bending stiffness was lost.

Other composite fabrication methods.

This paper investigated delamination failure in a unidirectional curved composite laminate.

The dcb test specimen was made of a unidirectional fiber reinforced laminate containing a thin insert at the mid plane near the loaded end.

Behavior of unidirectional composites.

The stack is defined by the fiber.

Behavior of unidirectional composites.

References 1 hart smith l j backing out composite lamina strengths from cross ply testing in comprehensive composite materials a.

A unidirectional ud fabric is one in which the majority of fibres run in one direction only.

The minor poisson s ratio 21 2 12 1 ee is also used in the equations below.

All tests are performed in laboratory conditions at room temperature.

Carbon fiber laminates unidirectional carbon fiber laminates are manufactured with 250 f cure carbon fiber pre preg carbon fibers impregnated with epoxy resin and cured with heat and pressure.

Zweben editors elsevier science.

12 and the shear modulus g12.

Thus unidirectional composite axial tensile specimens are often on the order of only 1 mm 0 040 inch thick.

A laminate is an organized stack of uni directional composite plies uni directional meaning the plies have a single fiber direction rather than a weave pattern.

Delamination was assumed to initiate at the location of the highest radial stress in the curved region.